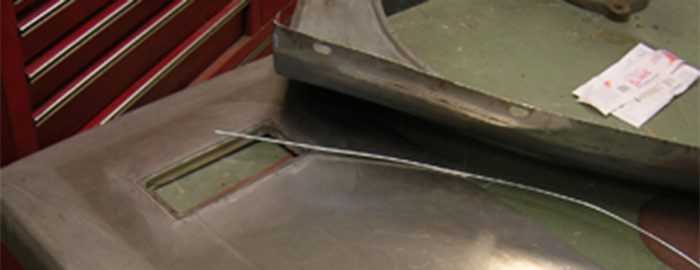

There are two Jaguar XK bodies in the shop going through some sheet metal repair. This body is laying upside down for easier access, but you can make out the familiar side vent on these cars. What might not be so obvious, however, is how much of a slight shape there is to the slab sides of a XK body. Getting these slight curves to line up with other panels takes more skill than it may seem.

Large sections for these bodies are available new, but sometimes it’s cheaper to have patches made, provided a skilled fabricator is on the job…

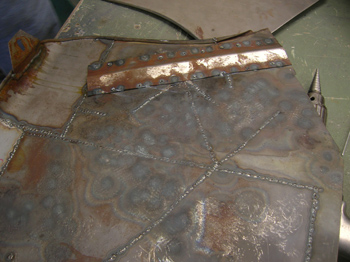

Here’s an example of a side panel repair gone horribly wrong. What began as a simple patch panel began to distort the large expanse of sheet metal. When the previous shop tried to shrink and stretch the deformed metal, it only got worse.

It looks like cuts were made to relieve the buckling sheet metal, then it was welded back together.

It got so bad that they even tacked in a stiffening piece behind the panel to try and control the warpage (top of the picture). They made up for lack of skill with a nice thick coat body filler and called it a day.

At a certain point, these repairs can only be salvaged with a new panel. Metal can only be worked so much before it becomes easier to start fresh. This panel was made in house by the Panel Shop.